Fabric filter | EMIS

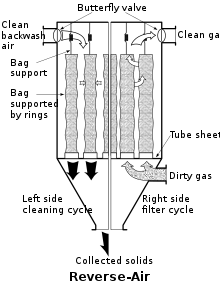

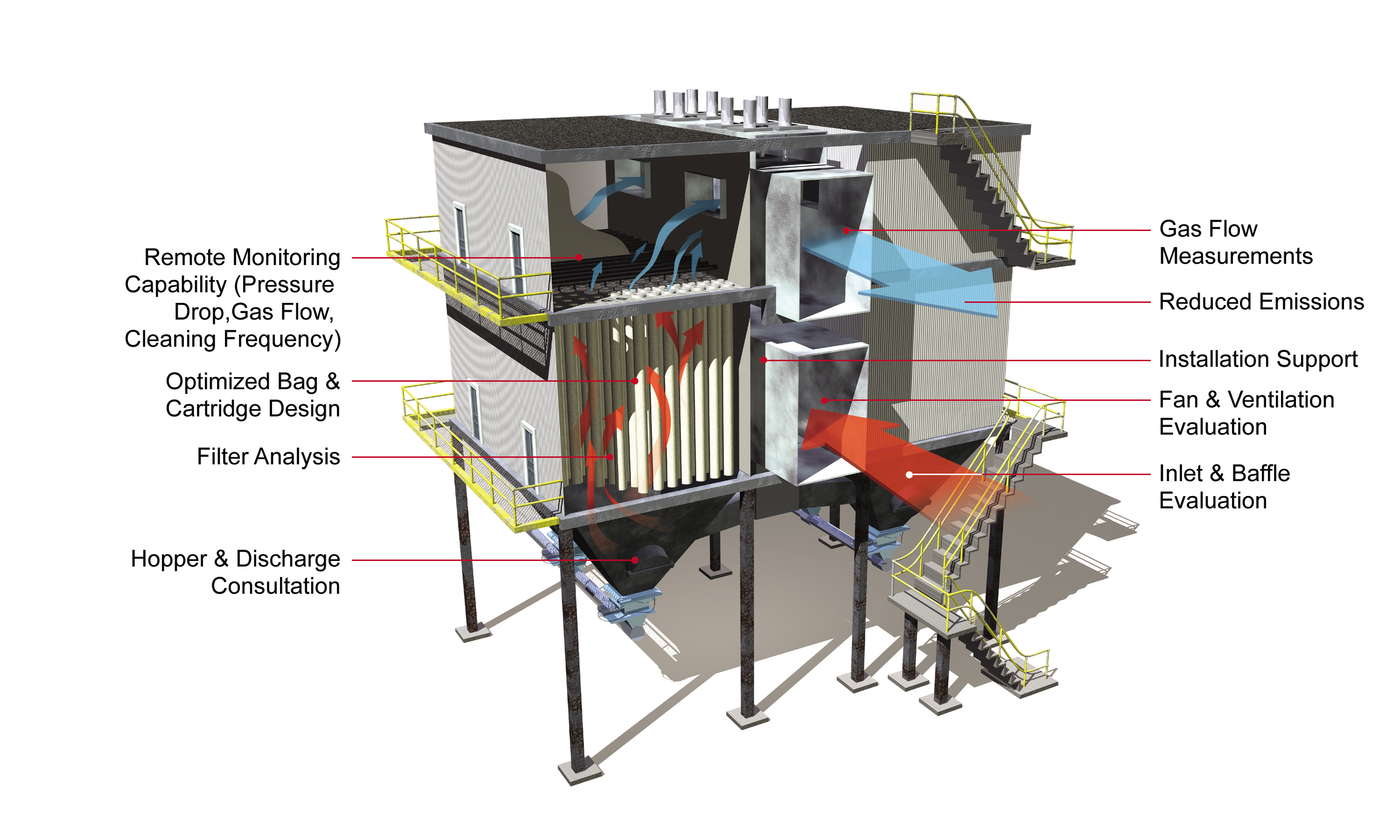

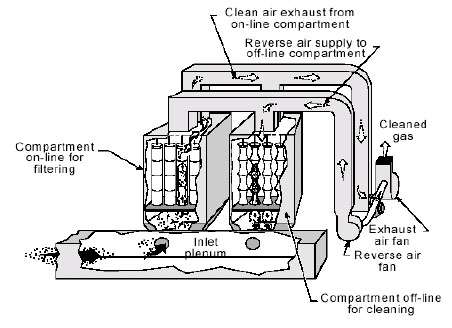

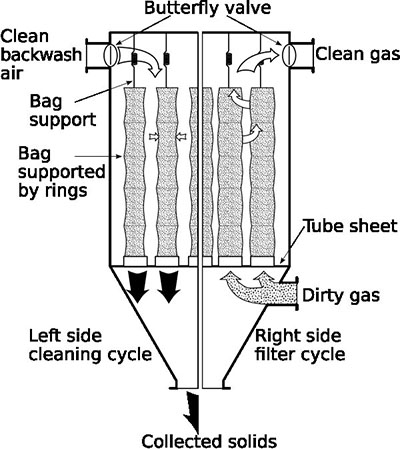

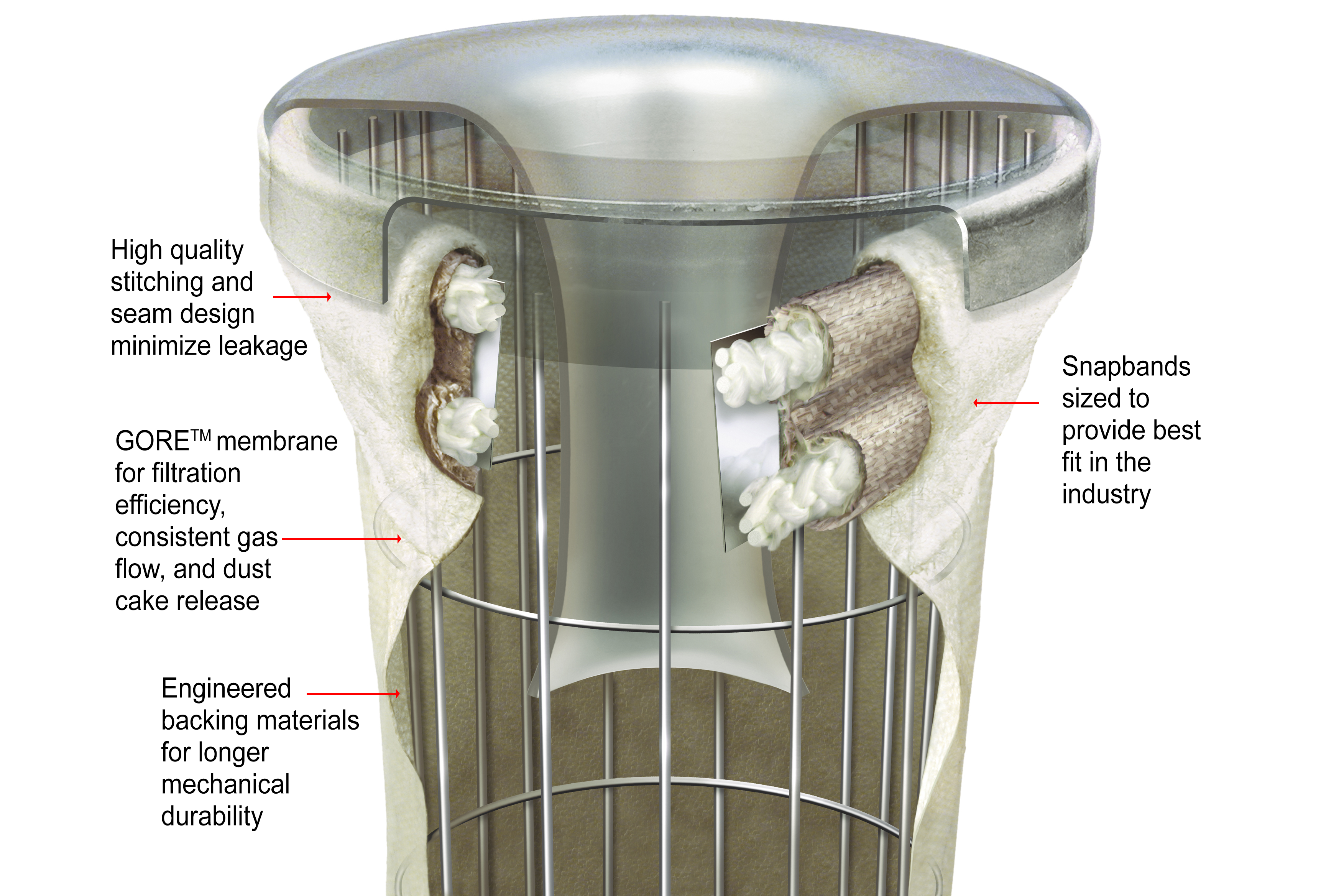

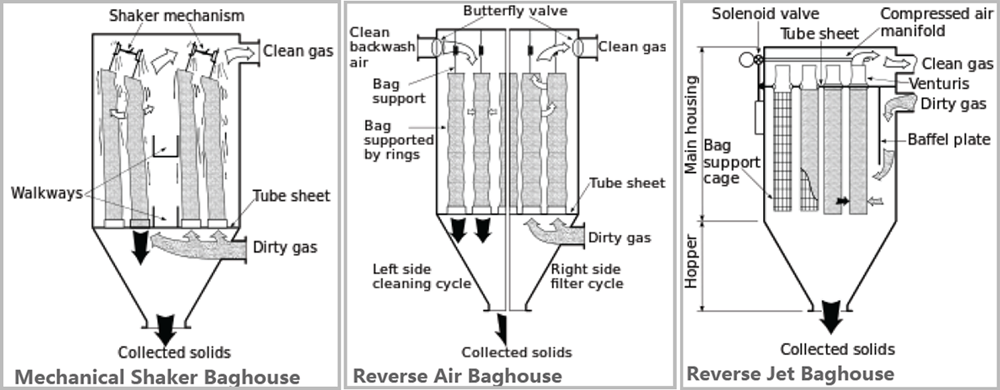

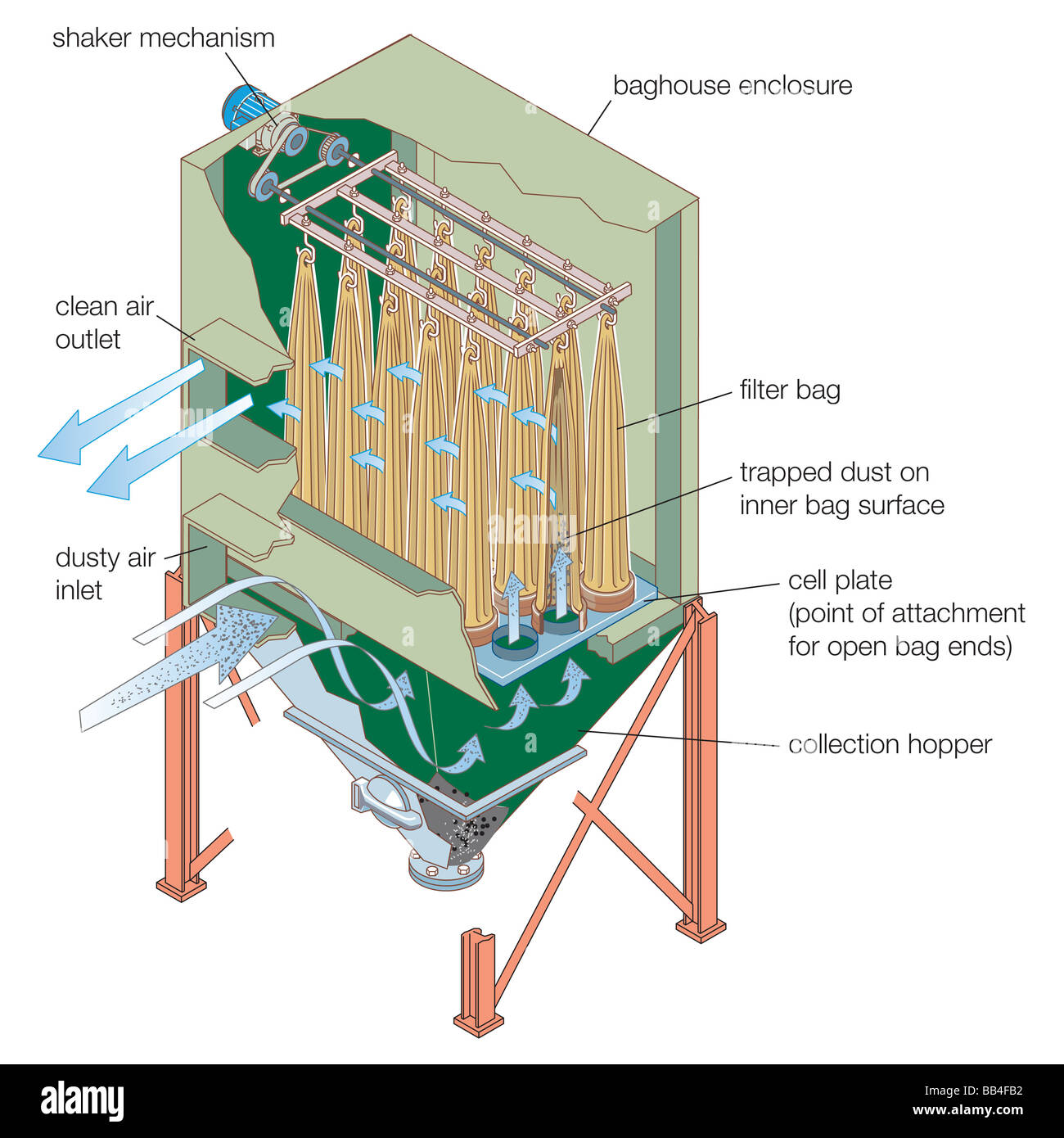

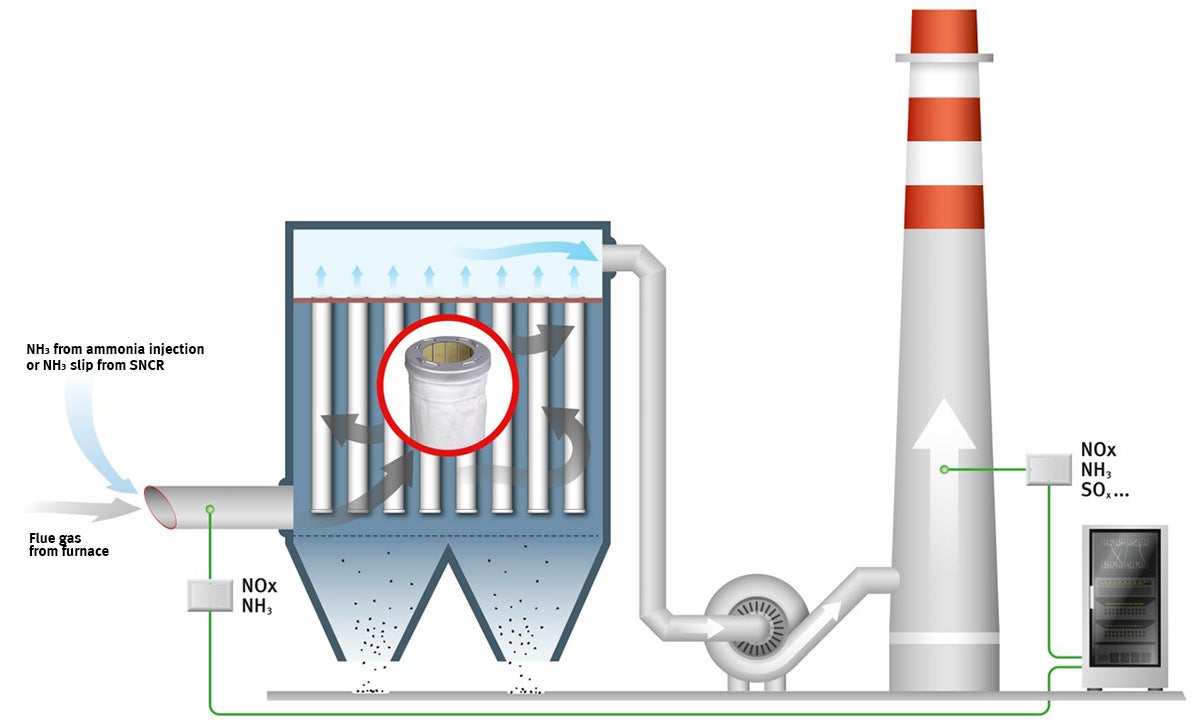

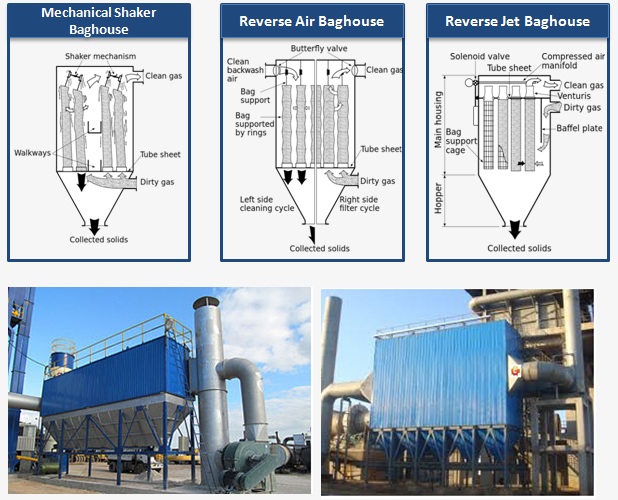

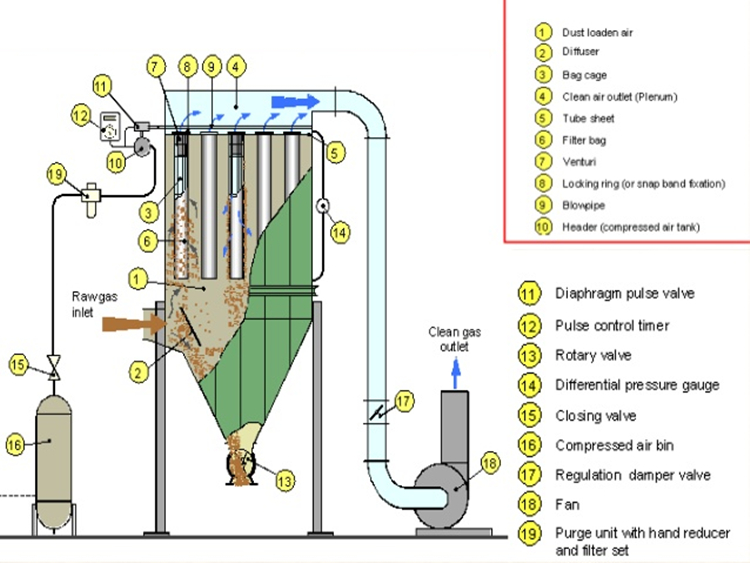

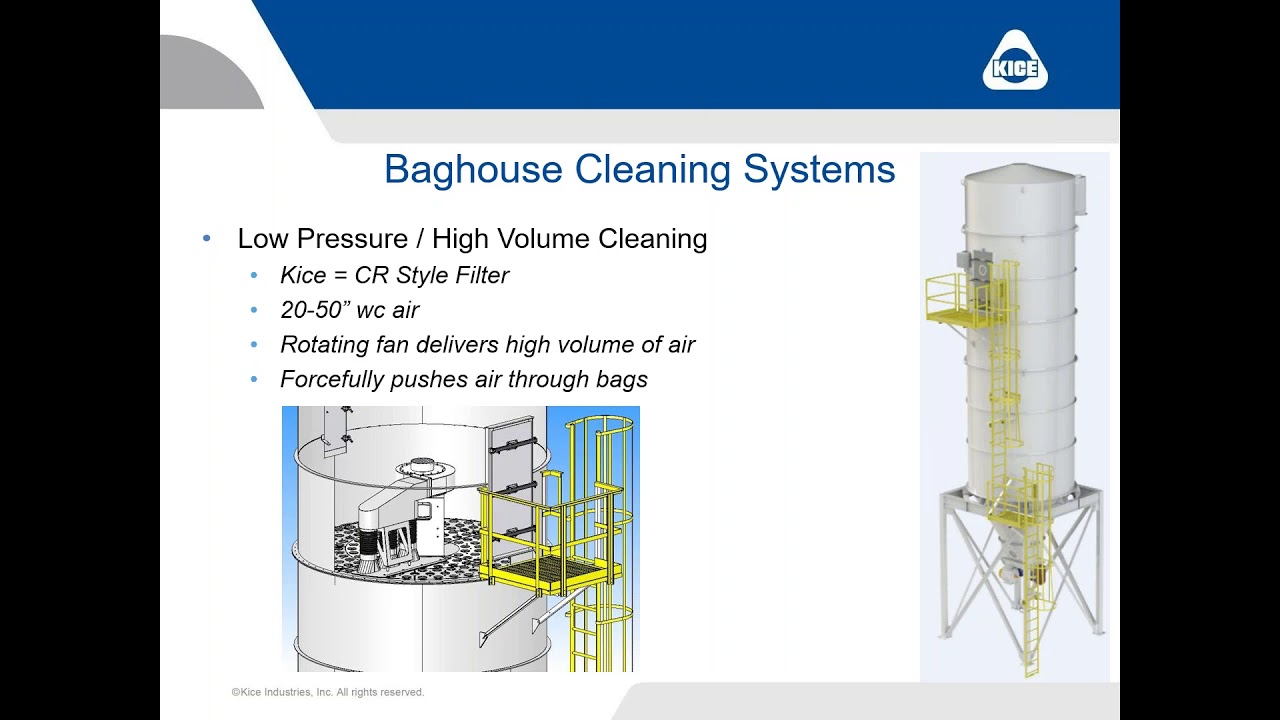

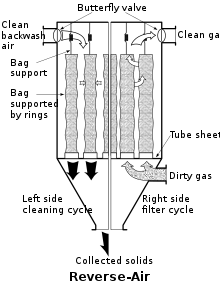

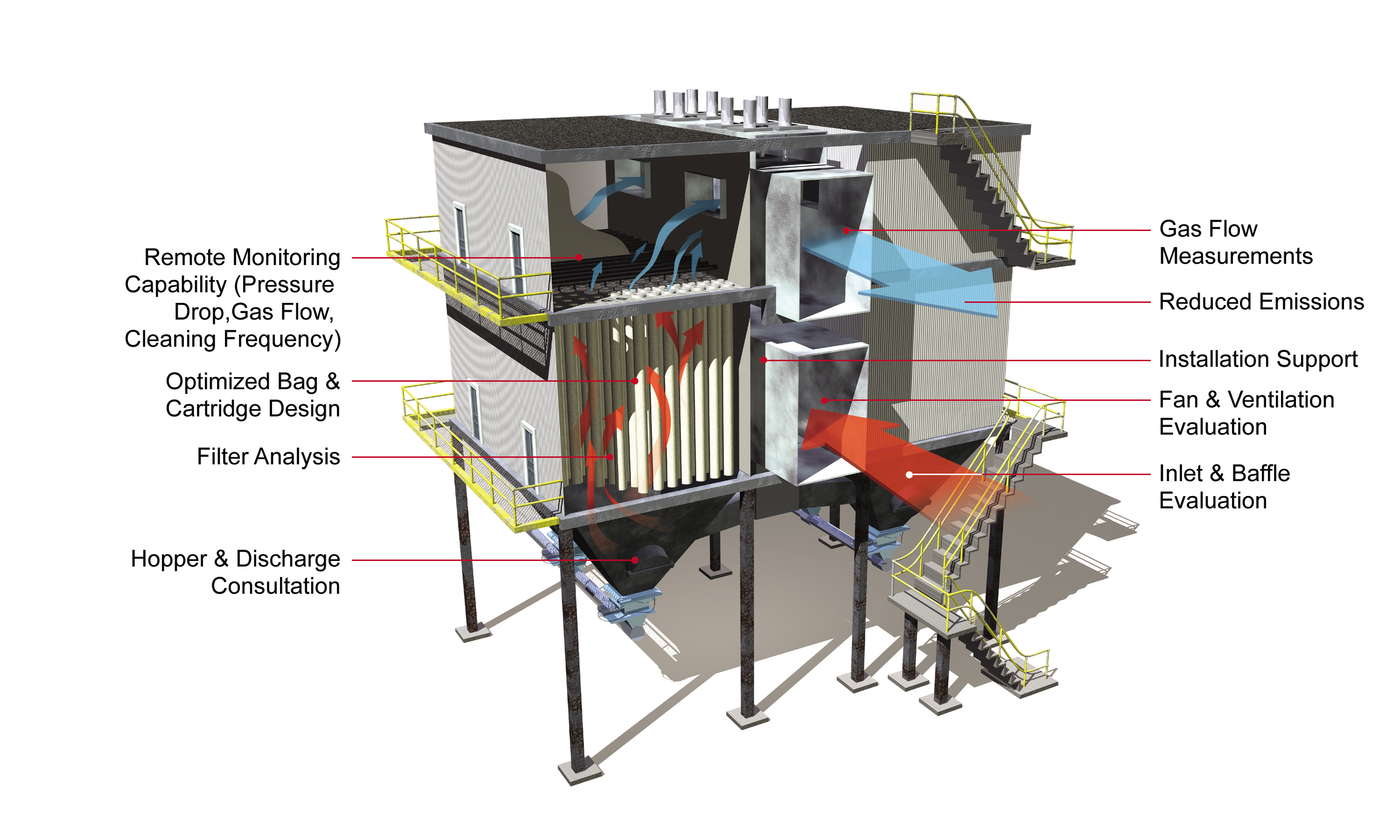

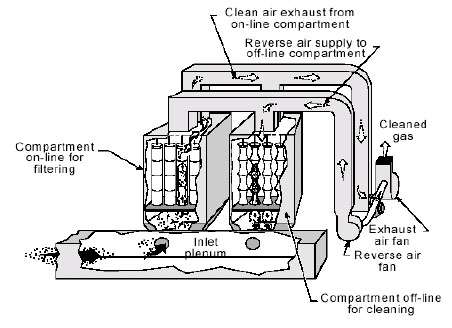

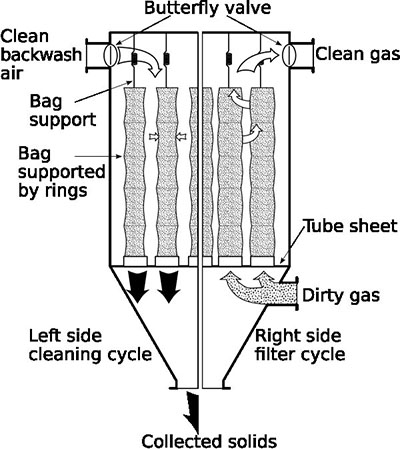

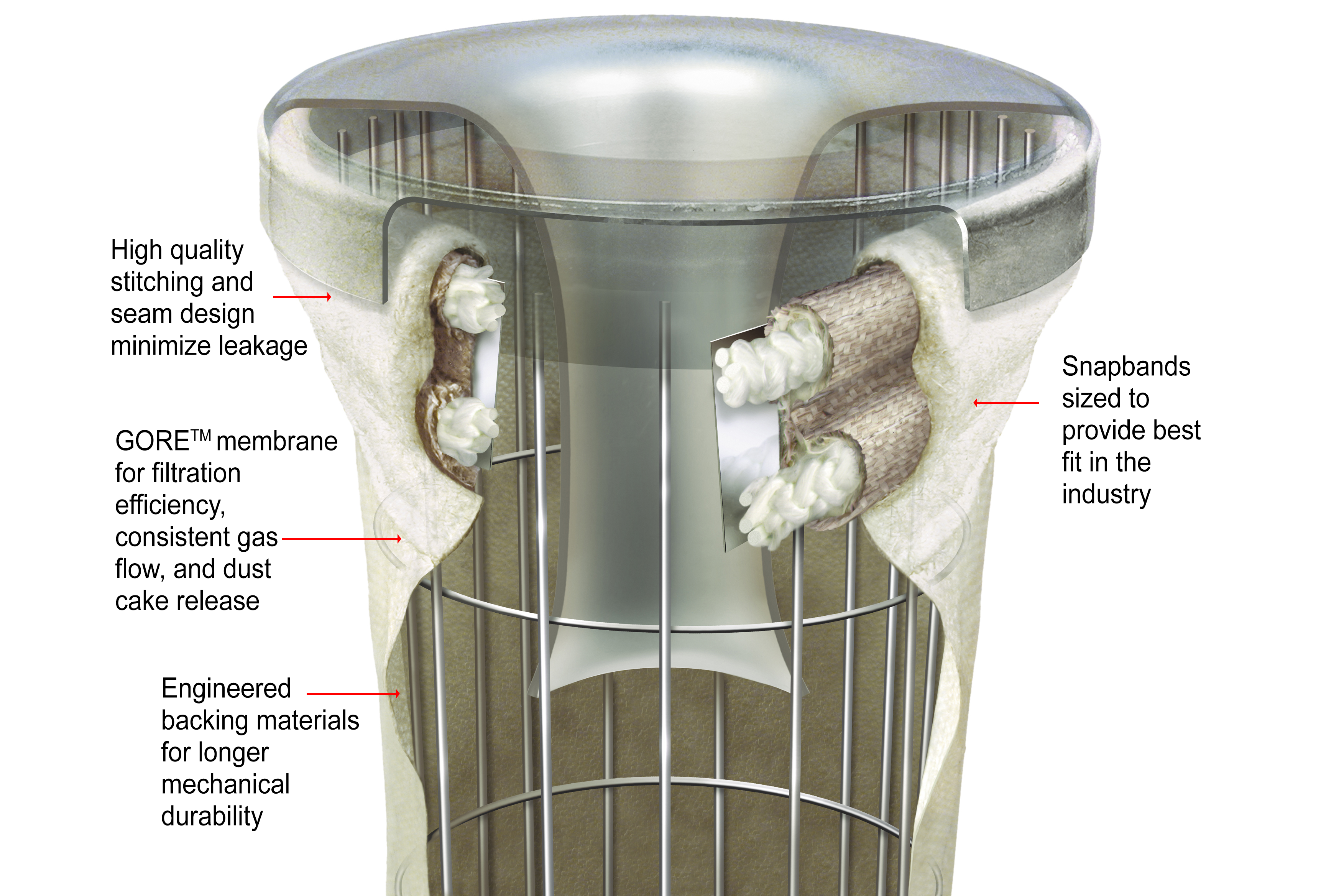

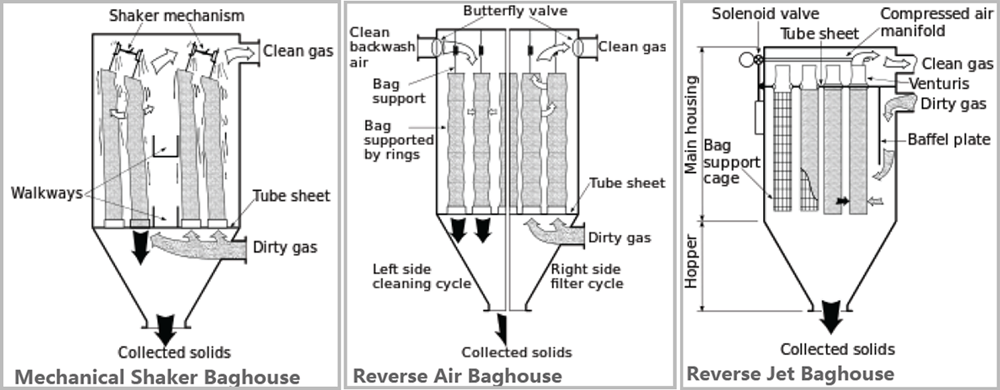

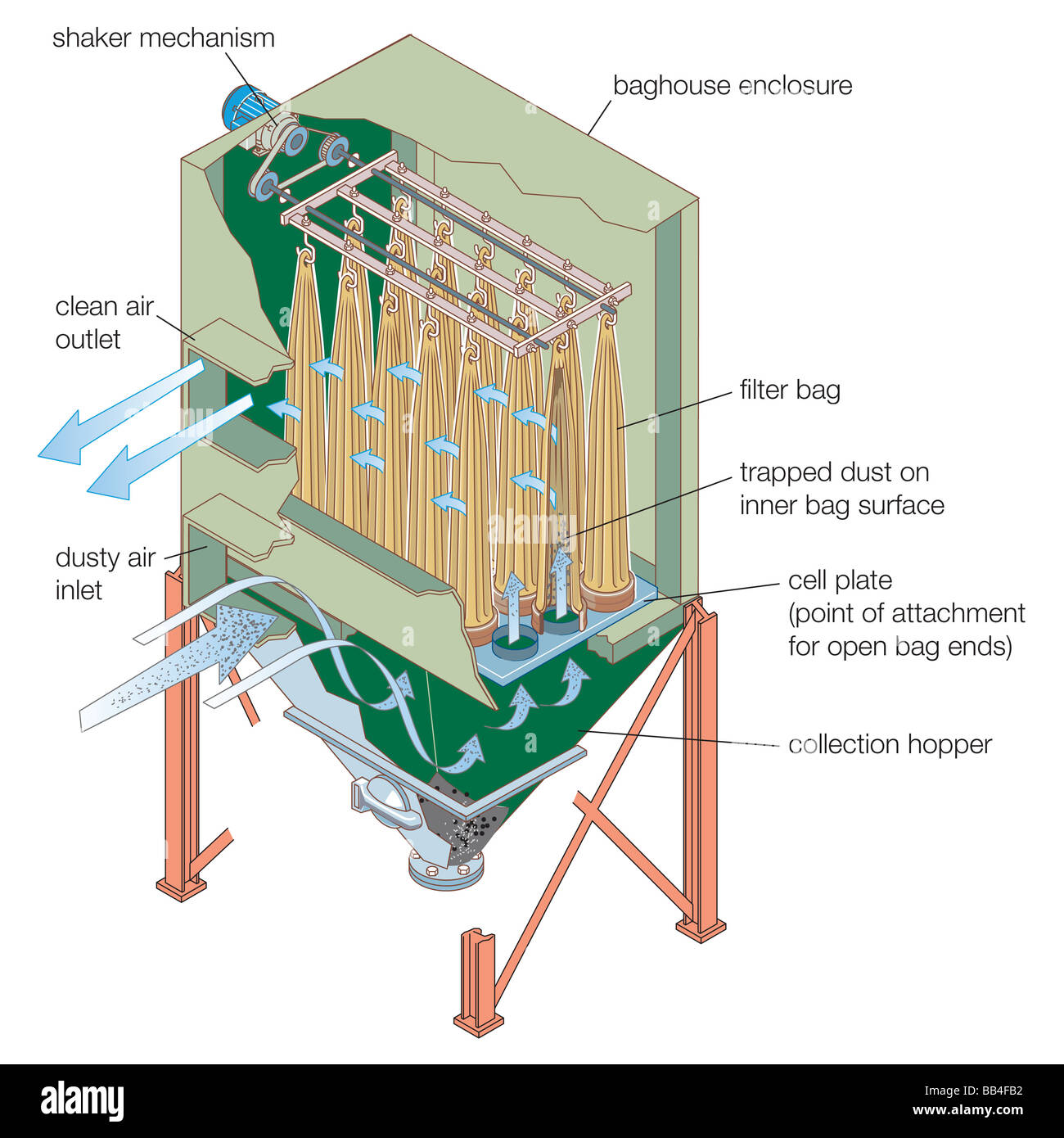

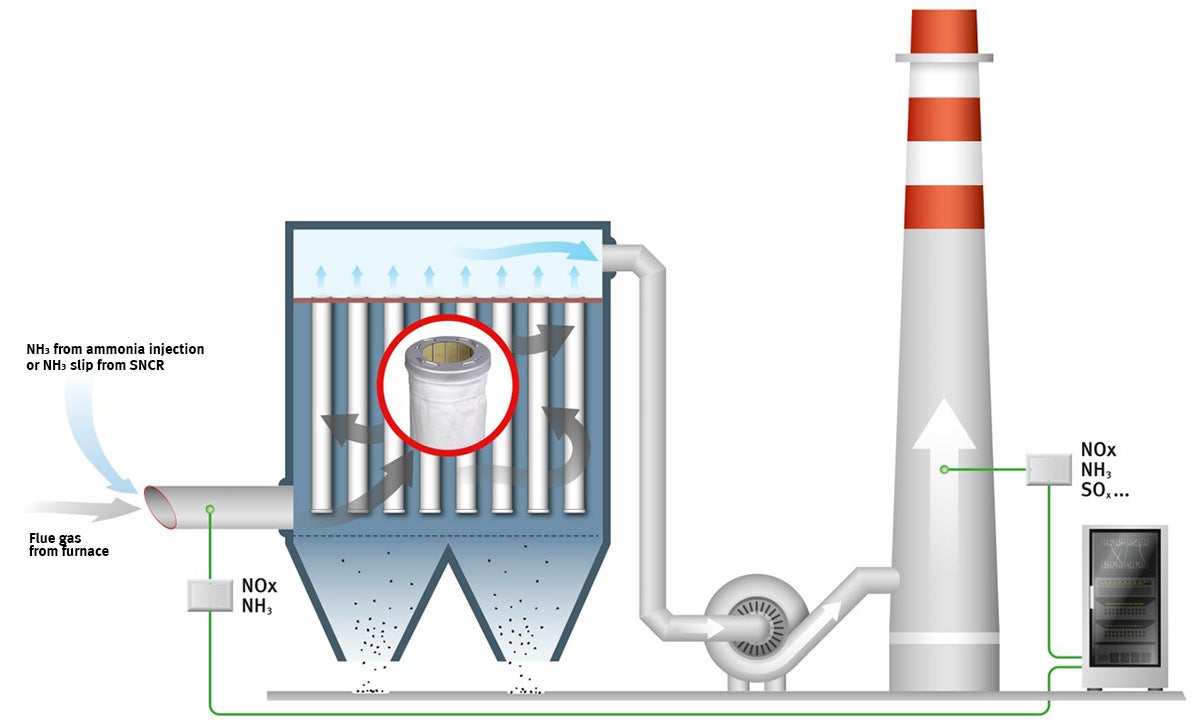

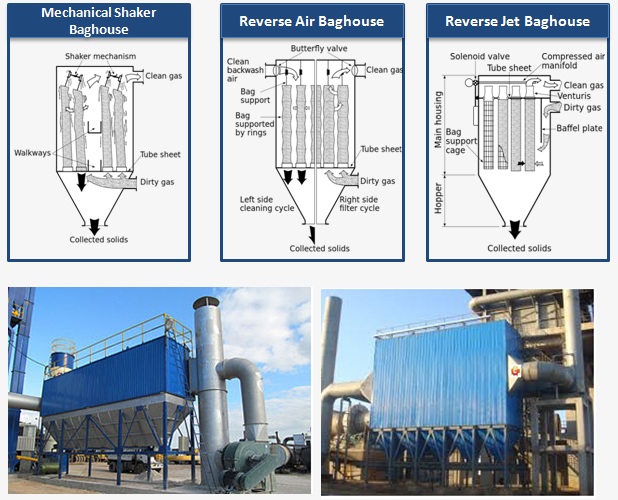

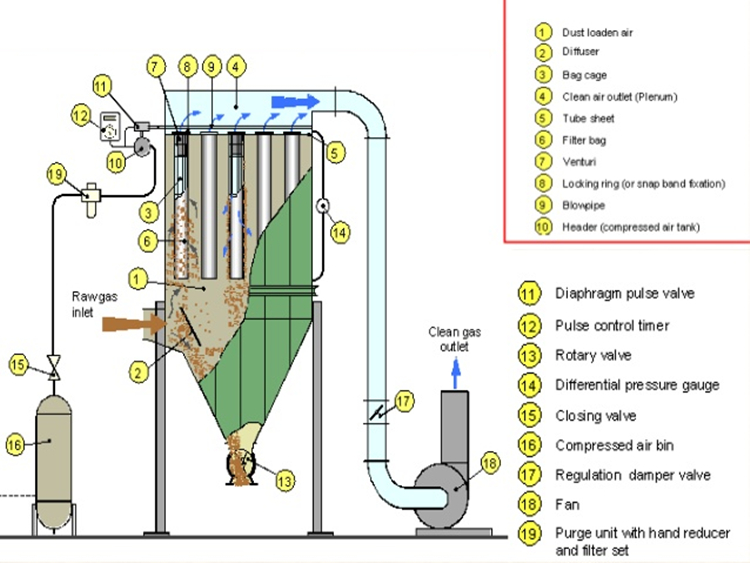

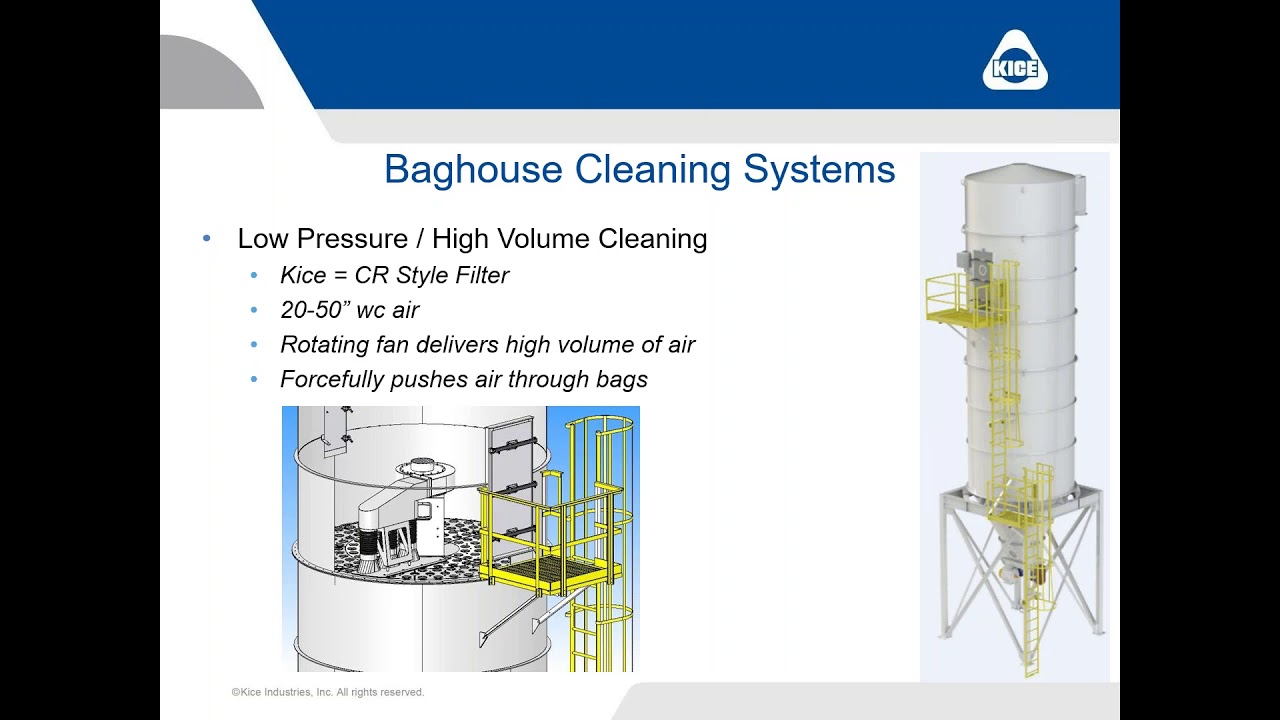

Fabric filter | EMISBaghouse A baghouse, also known as a bag filter, bag filter or fabric filter is a device that removes or releases gas from commercial processes outside the air. Electric power plants, steel mills, pharmaceutical producers, food manufacturers, chemical producers and other industrial companies often use bags to control the emission of air pollutants. The bags were widely used in the late 1970s after the invention of high-temperature tissues (for use in the filtration media) capable of supporting temperatures above 350 °F (177 °C). baghouse filterbag filterfabric filterUnlike , where performance can vary significantly depending on the process and electrical conditions, operating bags usually have a 99% or better particle collection efficiency, even when the particle size is very small. ContentOperation[ ] Most bags use long and cylindrical bags (or tubes) made of tissue or tissue as a filter medium. For applications where there is relatively low dust load and gas temperatures are 250 °F (121 °C) or less, folded and non-woven cartridges are sometimes used as a filter medium instead of bags. The gas or air charged with dust enters the bag and heads to the compartment of the bag. The gas is drawn through the bags, either inside or outside depending on the cleaning method, and a layer of dust accumulates on the surface of the filtration media until the air can no longer move through it. When a sufficient pressure drop occurs (ΔP), the cleaning process begins. Cleaning can take place while the baghouse is online (filtering) or is out of line (in isolation). When the compartment is clean, the normal filter will resume. The bags are very efficient particle collectors due to the powder cake formed on the surface of the bags. The tissue provides a surface where the dust accumulates through the following four mechanisms: A combination of these mechanisms results in the formation of the dust cake in the filter, which eventually increases resistance to gas flow. The filter must be cleaned periodically. Types[]Mechanical Shaker BaghouseReverse Air Baghouse Pulso Jet Baghouse Bags are classified by the cleaning method used. The three most common types of bags are mechanical agitators, reverse gas and pulse jet. Mechanical Agitators[ ] In the mechanical drainage bags, the tubular filter bags are fixed on a plate at the bottom of the bag and suspended from horizontal beams at the top. The dirty gas enters the bottom of the bag and passes through the filter, and the dust accumulates on the inside surface of the bags. The cleaning of a mechanical shaving bag is achieved by stirring the upper horizontal bar from which the bags are suspended. produced by a motorized shaft and creates waves in the bags to shake the dust cake. Shaker bags vary in size from small handshake devices to large compartmentalized units. They can operate intermittently or continuously. Intermittent units can be used when processes work on a batch base; when a batch is completed, the baghouse can be cleaned. Continuous processes use compartment bags; when a compartment is cleaned, airflow can be diverted to other compartments. In the stirring bags, there should not be inside the bags during the agitation cycle. Pressures as low as 5 pascals (0.00073 psi) can interfere with cleaning. The shaker bags are relatively low, so the space requirements are quite high. However, due to the simplicity of design, they are popular in the mineral processing industry. Reverse air[] In the outdoor baghouses, the bags are open on a cell plate at the bottom of the bag and are suspended from an adjustable perch frame at the top. The dirty gas flow normally enters the bag and passes through the bag from the inside, and the dust accumulates inside the bags. Outdoor bags are compartmented to allow continuous operation. Before starting a cleaning cycle, the leak stops in the compartment to be cleaned. Bags are cleaned by injecting clean air into the powder collector in an inverse direction, which presses the compartment. Pressure makes the bags collapse partly, causing the dust cake to break and fall into the bottom hopper. At the end of the cleaning cycle, the reverse air flow was discontinued and the compartment is returned to the main current. The flow of dirty gas helps keep the shape of the bag. However, to avoid the total collapse and lure of fabric during the cleaning cycle, rigid rings are caught in the bags at intervals. The space requirements for an outdoor baghouse are comparable to those of a stirring baghouse; however, maintenance needs are somewhat higher. Pulse Jet[] In reverse pulse injection baghouses, individual bags are supported by a metal cage (filter cage), which is fixed on a cell plate at the top of the bag. Dirty gas enters from the bottom of the bag and flows from outside to inside the bags. The metal cage prevents the collapse of the bag. Bags are cleaned by a short injection burst through a common manifold over a row of bags. The compressed air is accelerated by a nozzle mounted at the top of the inverse jet bag of the bag. Since the duration of the compressed air explosion is short (approximately 0.1 seconds), it acts as an air bubble that moves quickly, traveling through the entire length of the bag and making the surfaces of the bag flex. This bending of the bags breaks the dust cake, and the disassembled dust falls into a storage hopper below. Converse pulse injection powder collectors can be operated continuously and cleaned without flow interruption because the compressed air flow is very small compared to the total volume of dusty air through the collector. Because of this continuous cleaning function, reverse injection powder collectors are usually not compartmentalized. The short cleaning cycle of inverse jet collectors reduces the recycling and redeposing of the dust. These collectors provide a more complete cleaning and refurbishing of bags than the cleaning methods of the agitator or the reverse air. In addition, the continuous cleaning function allows them to work with air ratios to upper body, so space needs are lower. A digital sequential rotates in the solenoid valve at established intervals to inject air into the blow pipe and clean the filters. Considerations of cleaning[] Hundred horns[] Some sacks have installed to provide additional vibration to increase dust cleansing. The horns, which generate high intensity, low frequency, are lit right before or at the beginning of the cleaning cycle to help break the bonds between particles on the surface of the filtration media and help eliminate the dust. Rotating Mechanical Cage[]In addition to the most common cleaning methods of baghouse is a relatively new way to use the bag filter cage. The rotating mechanical cage option consists of a fixed cage attached to the cellular plate. In addition to the fixed mechanical cage is a nesting cage inside the fixed cage that can be acted to clean the inside of the filter bag. This wiring action performs the same desired effect of creating a lump that loosens the particles as the cage moves. Cleaning sequences[] Two types of main sequences are used to clean bags: Intermittently cleaned bags are composed of many compartments or sections. Each compartment is periodically closed from the incoming dirty gas current, cleaned and then returned online. While the individual compartment is out of place, the gas flow is diverted from the compartment area. This makes it unnecessary to close the production process during cleaning cycles. Bag compartments always cleaned. A compressed air explosion temporarily interrupts the collection process to clean the bag. This is known as pulse jet cleaning. Pulse jet cleaning does not require taking off-line compartments. Continuously cleaned bags are designed to avoid complete closure during the maintenance of bags and failures in the primary system. Performance[] The performance of the house depends on the gas inlet and outlet temperature, pressure drop, and gas. The , humidity, acid , and the loading of particles and distribution of gas current size are also essential factors. Design variables[] Pressure box, filter drag, body-to-body air ratio and collection efficiency are essential factors in the design of a bag. Means of filtration[ ] Facial filter bags are oval or round tubes, usually from 15 to 30 feet (4.6 to 9.1 m) long and from 5 to 12 inches (130 to 300 mm) in diameter, manufactured with tissue or felt material. Depending on the chemical content and/or humidity of the gas flow, its temperature and other conditions, the bags can be built with cotton, nylon, polyester, fiberglass or other materials. Non-woven materials are or feel or membrane. Non-woven materials are attached to a tissue backrest (crym). Felted filters contain randomly placed fibers supported by a tissue backup material (script). In a membrane filter, a thin and porous membrane is linked to the glaze. High-energy cleaning techniques, such as pulse jet, require felt tissues. Non-woven filters Filters have a defined repeated pattern. Low-energy cleaning methods, such as agitated or reverse air, allow tissue filters. Various tissue patterns such as , knit twill, or sateen weave, increase or decrease the amount of space between individual fibers. The size of the space affects the strength and permeability of the tissue. A tighter tissue corresponds to low permeability and, therefore, a more efficient capture of fine particles. WovenReverse airbags have anticollapso rings sewn in them to prevent sarcastic when cleaning energy is applied. Pulse jet filter bags are compatible with a metal cage, which keeps the taut fabric. To lengthen the life of the filter bags, a thin layer of the PTFE membrane (teflon) can be attached to the filter side of the tissue, keeping the dust particles embedded in the filter media fibers. Some bags use folded cartridge filters, similar to what is found in home air filtration systems. This allows a much greater surface for greater flow at the cost of additional complexity in manufacturing and cleaning. See also[] References[]External links[] Navigation menu Personal tools Named spaces Variants Views More Search Navigation Contributed Tools Printing/exporting Languages

An official website of the United States government. Main menuMonitoring by Control Technique - Fabric FiltersDescription A fabric filter, sometimes known as a bag, uses the fabric filtration to remove particles from the contaminated gas current by depositing particles into fabric material. The filter's ability to collect small micrometer and submicrometer particles is due to the accumulated dust cake and not the tissue itself. The filter is usually in the form of cylindrical cloth bags, so the names "filter of fame" or "bag case", but may be in the form of cartridges that are constructed of fabric, sintered metal or porous ceramic. In general, fabric filters are able to collect efficiencys above 99 percent. There are three types of fabric filters. Each type differs in the method used to clean the filter material. As the dust accumulates on the filter surface, the pressure increases through the filter. To avoid excessively high pressure drops, the filter material is regularly cleaned. The most common methods of cleaning are tremor, reverse air and reverse pulse or pulse jet. Shaker fabric filter collectors clean the bags gently stirring. The agitator collector has a tube blade between the vertical shell and the hopper. The open funds of the cylindrical bags are attached to the holes in the tube sheet, and the closed covers of the bags are attached to the agitation mechanism at the top of the box. The flow of contaminated gas enters the hopper, flows through the holes in the tube leaf and inside the vertical bags. As the bags are closed at the top, the gas flow flows through the bags, leaving a powder cake inside. Periodically, the flow of gas through the collector or compartment stops and the bags shake to clean them. Dislodged dust cake falls into the hopper and withdraws from the collector. Converse air filter collectors are similar to agitation collectors. The reverse air collector has a tube foil between the shell and the hopper. The bottoms of the bags are glued to holes in the tube sheet; however, the closed caps of the bags are subject to a support structure at the top of the housing that holds the bags under tension. The flow of contaminated gas enters the hopper, flows to and through the bags, leaving the dust cake back inside. To clean the bags, the flow of gas is stopped through the compartment and another flow of gas is introduced that flows in the reverse direction. This gas flow is usually taken from the clean gas current that is discharged from operating compartments. To prevent the bags from falling completely during the reverse airflow, the rigid rings are caught in the bags at intervals along their length. The dust cake loosed by the reverse air flow falls into the hopper and withdraws from the collector. Inverse pulse or pulse collectors clean up bags using short-lived compressed air pulses. The collector has a tube leaf that is located near the top of the vertical housing, and the bags hang from the holes in the tube sheet. A wire mesh cage is found inside the bags to prevent them from failing. The flow of contaminated gas enters the side or through the collector's hopper and flows to the bags and up through the tube leaf, leaving the dust cake on the outside of the bags. The cleaning is achieved through the direction of the compressed air pulse to one or more rows of bags, while the other bags continue to provide filtration. The collector usually does not close or isolate from the flow while cleaning. The dust cake unlocked by the compressed air pulse falls into the hopper and withdraws from the collector. The performance of the fabric filter can be performed by the conditions to which the fabric is exposed and the cleaning frequency. The minimum operating temperature is especially important when acid gases are expected to be present in the gas current. Lower temperatures mean that acid gases have the potential to condense and corrode the fabric filter cap and other metal parts. Condensing can also cause bag blinder, which blocks air flow through the bag. Fabric filters are also susceptible to damage caused by high temperatures. The specific information about the fabric filters can be found in the EPA Fact Sheets and the EPA Air Pollution Control Manual, Section 6, Chapter 1 Bags and Filters (Sixth Edition). For more information, see the Monitoring Information box The best performance indicators of the fabric filters are the concentration of particulate matter outputs, which can be measured with a system of continuous monitoring of particulada material emissions (CEMS) or a bag leak detection system used to monitor breakages and bag leaks. Monitoring opacity is also an indicator of the performance of the fabric filter. Other performance indicators include pressure differential, input temperature, temperature differential, exhaust gas flow, cleaning mechanism operation and fan current. The Technical Guidance Document (TGD) on Compliance Guarantee Surveillance is a source of information on monitoring approaches to different types of control devices. The specific information provided in the CAM TGD related to fabric filters includes the example of CAM shipments based on case studies of actual installations. For more information, see the box CostsThe fabric filters are discussed in the EPA Air Pollution Control Manual*, (60 pp, 272 K, ). The costs of the monitoring systems, both the Continuous Emission Monitors and the parametric surveillance systems, are addressed in the EPA Air Pollution Control Manual*, (42 pp, 540 K, ). Specific tools have been developed to estimate the cost of fabric filter when used to control the particled matter of coal power plants and utility boilers. As indicated above in the monitoring section, the performance indicators of the fabric filters include the output concentration of particulate matter, which can be measured with a CEMS particule matter. The costs associated with the purchase and installation of a CEMS can be estimated using the model version EPA CEMS Cost 3.0For more information on the costs and cost model CEMS, see the box More about Fabric FiltersTypic Shaker BaghouseTypic Reverso Air BaghouseTypics Jet Baghouse Pulse Feature diagrams courtesy of North Carolina State University Monitoring & Rules CAMMore about Fabric Filters & Costs Last updated on 8 January 2021

Schematics of a baghouse filter. | Download Scientific Diagram

Baghouses and Baghouse Filters Selection Guide | Engineering360

Baghouse - Wikipedia

Neundorfer | Optimizing the Performance of Air Pollution Control Equipment

Baghouse filter | technology | Britannica

Dryer Air Baghouse Filter | Biofuels Academy

GORE® Industrial Baghouse Filters: Membrane Construction | Gore

Schematic diagram of the pilot-scale pulse-jet baghouse. A, pressure... | Download Scientific Diagram

Fabric Filter Diagram - DesaignHandbags

Monitoring by Control Technique - Fabric Filters | Air Emissions Monitoring Knowledge Base | US EPA

Baghouses and Baghouse Filters Selection Guide | Engineering360

Reverse-Air-Baghouse-Diagram – Baghouse.com

Baghouse - Wikipedia

Reverse-Gas Fabric Filter - an overview | ScienceDirect Topics

5.8. Filter systems 5.8.1 Principle of operation, layout Filter systems are the main alternative for ESP systems discussed in th

Working, Design Considerations and Maintenance of Bag Type Fabric Filters

Baghouse Filter For Dust Collection Producer US - DHA Filter

GORE® Industrial Baghouse Filters: Membrane Construction | Gore

Bag Filter in Boilers & Bag filters Working Principle | Thermodyne Boilers

Baghouses and Baghouse Filters Selection Guide | Engineering360

Bag Filters – Redecam Group

Pulse Jet Fabric Filter Design - DesaignHandbags

Fabric Filter - an overview | ScienceDirect Topics

Custom Designed Dust Collectors - Baghouses - GCE Systems

What is industrial dust collector and baghouse filter bag?

Working, Design Considerations and Maintenance of Bag Type Fabric Filters

Baghouse Inspection - Certified Commercial Property Inspectors Association

Baghouse employing an array of fabric bags for filtering the Stock Photo - Alamy

A schematic diagram of the pulse-jet bag filter test facility. | Download Scientific Diagram

Differential Pressure Measurement across Baghouse

Baghouse Filter | Wet Scrubber | Electrostatic

Fabric Filters - SolidsWiki

Pulse Jet Solenoid Valve - How They Work | Tameson

Industrial Baghouse Filter Bags for the Cement Industry | Gore

Bag House Filter, Baghouse Filters, Supplier, Manufacturer, Mumbai, India

applied sciences

Baghouse Pulse Dust Collector / Bag Filter / Dust Remover_Lifeierte Filter

Pulse Jet Bag Filters: The Ultimate FAQ Guide | Filson Filter

Neundorfer | Optimizing the Performance of Air Pollution Control Equipment

Baghouse Filter Maintenance and Troubleshooting - YouTube

Posting Komentar untuk "baghouse filter diagram"